-

Whatsapp / Wechat+8618007570077

Main construction process requirements

Metal decorative line

1) Aluminum alloy line

Aluminum alloy line is a strip shape formed by extruding pure aluminum with manganese and magnesium

Materials.

1. Features

Aluminum alloy line has the characteristics of light weight, high strength, corrosion resistance, wear resistance and high stiffness. After anodizing and coloring, the surface has bright metallic luster, good light resistance and weather resistance. The surface can also be coated with solid and transparent electric autumn paint film, which makes it more beautiful and applicable.

2 purpose

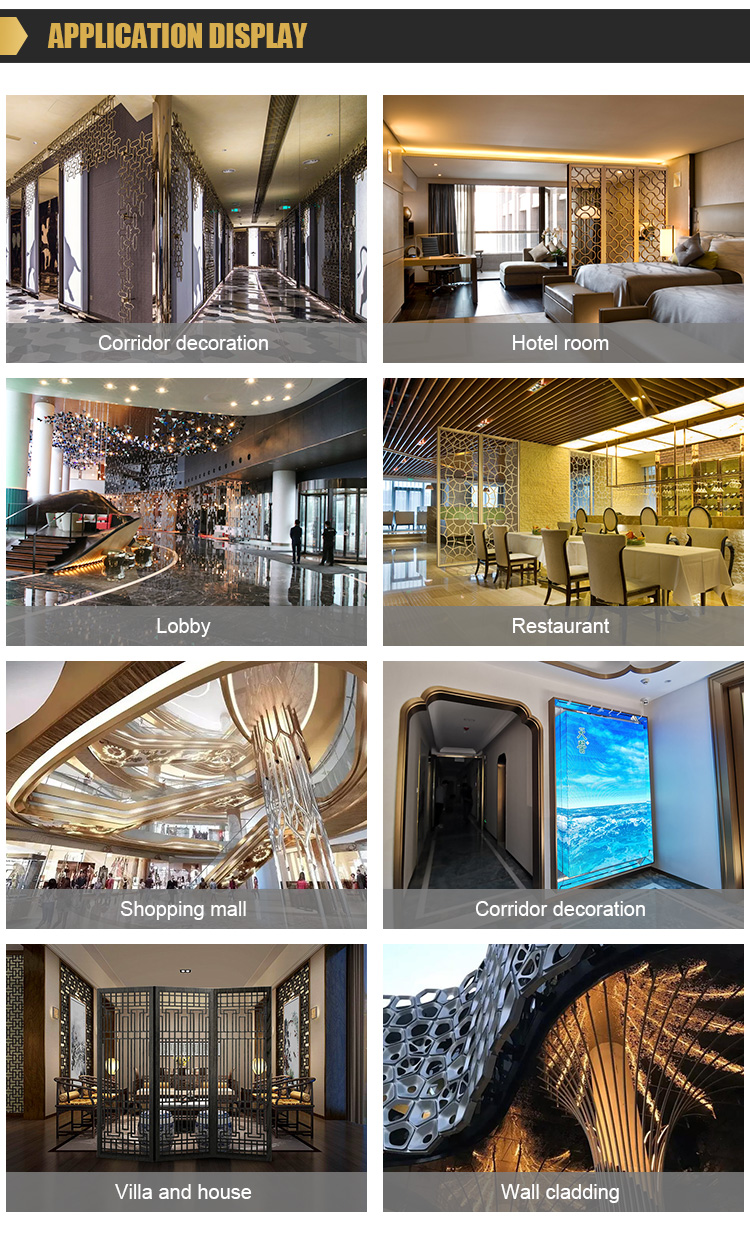

The aluminum alloy line can be used for the edge pressing line and withdrawal line of decorative surface, as well as the frame edge line of decorative painting and decorative mirror. It is used as frame or frame on billboard, light box, display board and indicator board, and as sealing line of some equipment on wall or ceiling surface. The utility model is used to draw the edge of the aluminum alloy line on the door of the carpet.

3 specifications

The aluminum alloy line mainly has the angle line, the picture frame line, the carpet retraction line and so on several kinds. Corner line can be divided into equilateral line and unequal edge line.

·Key points of installation and construction

1 installation method

(1) The installation of stainless steel line and copper wire line adopts the method of closing without nail strip on the surface. The process is as follows:

First, fix a piece of wood liner on the four positions with nails. The width and thickness of the wood liner is slightly smaller than the inner diameter of the stainless steel or copper wire groove.

Then apply epoxy resin adhesive (all-purpose adhesive) on the wooden strip, remove the epoxy resin in the stainless steel groove, and then install the line on the wood strip.

If stainless steel lines have modeling, wood should also be made to shape.

(2) Generally, the surface of stainless steel line letter is pasted with a protective layer of plastic tape, which should be torn off from the stainless steel line groove after finishing construction. If there is no plastic tape protective layer on the surface of the line groove, a layer of 6-6-48 metal line installation method should be mapped before construction to avoid damaging the line surface during construction.

2. Precautions

(1) The butt joint dimension of stainless steel system and copper wire bar at the angle position should be spliced with 45. When cutting, it should be on the 45° angle fixer and cut off with hacksaw blade. Pay attention not to damage the surface during the cutting operation.

(2) Grinding wheel cutting machine is not allowed to be used for cutting stainless steel and copper wire bars to prevent discoloration after heating. The spliced surface cut off shall be leveled with assorted files.