The stainless steel screen partition is very beautiful, so it is made in this way

The stainless steel screen partition is very beautiful, so it is made in this way

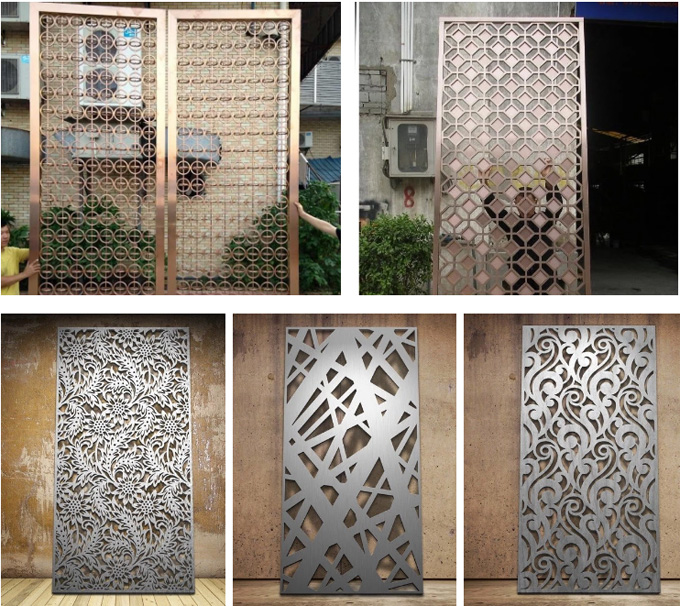

Stainless steel decorative screen not only has corrosion resistance, aging resistance, easy production and processing, easy to clean and other high quality characteristics, and in the five-star hotel, engineering decoration, home decoration level is very popular, how to process high quality customized stainless steel decorative screen, the next face of stainless steel decorative screen production to detail.

A, stainless steel decorative screen processing types are what kinds?

1. Welded stainless steel decorative screen

Custom stainless steel screens include spot welding and seamless welding.

According to the specifications of control materials, we can produce high-grade engraving products.

Spot welding is to separate the appropriate width, and then stitching and spot welding.

The direction of spot welding is tail-based.

Therefore, all welding screens are basically based on spot welding plus several kinds of full welding: such as argon arc welding, grinding, and surface treatment. The difference is that spot welding is on the inside of the solder joint, while all welding is on the front and outside of the solder joint.

The surface is then polished, since all welds need to cover the area with cracks, and of course, only the area that can be burnable can be fully welded;

After the processing is completed, the custom screen surface is vacuum plated.

2. Laser cutting hollow decorative screen

Most stainless steel custom screens are mainly made of materials. The stainless steel plate is made of various styles of graphics by laser cutting, then the burr is removed, the surface is processed, and then the color is processed after the splicing of the frame.

3. Aluminum plate carving decorative screen

Engraving generally uses aluminum plate, according to the different image requirements and then customized production, the final processing of the desired stainless steel custom screen graphics.

Two, what are the details of stainless steel decorative screen processing?

1, cutting, avoid one step wrong, wrong step by step.

Adhere to the material of the material should check the cutting Angle of the material to avoid the length of the material mixing, rough dimensions.

This leads directly to inaccurate rear soldering.

2, check the solder joint.

Spot welding must not be welded on the front, affecting the appearance.

Pay attention to the thickness of the material, the surface should not be distorted, and the solder joints should not be too large.

Look at the welding technique of welder, look at the welding quality.

3, look at the quality of grinding and polishing.

The beauty of stainless steel decorative screen components, grinding and polishing is very important, the surface grinding can not be ground too large area, can not be ground too deep, after polishing, the surface can not have sand holes, can not have scratch marks, far from the folding of printing, wave grain.

Add:No.18 Tongken Road,Nanken Zone,Longjiang Town, Foshan, Guangdong, China

Add:No.18 Tongken Road,Nanken Zone,Longjiang Town, Foshan, Guangdong, China  Tel:+86-757-22287859

Tel:+86-757-22287859 Fax:+86-757-22287858

Fax:+86-757-22287858 Email:sales@steelaman.com

Email:sales@steelaman.com Sale Tel:+86-18007570077

Sale Tel:+86-18007570077  Contacts:Yugo Yip

Contacts:Yugo Yip